Hard Chrome Plating is used in a variety of industrial applications and is known primarily for its strength, corrosion resistance, excellent wear and lubricating properties. It can be applied to a variety of base metals to strengthen or repair equipment and components returning them back to the correct dimensions without compromising the original material properties.

At Precision Equipment we have three, large hard chrome plating tanks in operation capable of plating up to 40” diameter and in some cases, up to 267” long (4-½” maximum diameter). All of our tanks utilize the HEEF© 25 plating process which provides a harder, more durable chrome surface than conventional chromic baths. We have some of the largest plating capacity in our region and a reputation for quality and punctuality. Upon request, Precision Equipment is capable of providing Hard Chrome Plating to Quality Control Standards QQ-C-320B or AMS-2460.

Precision Equipment is a premier heavy industrial repair shop with decades of experience across a number of industries. Our clients often come to us when other repair facilities or OEM suppliers are unable to meet expectations for quality and/or lead-times. Our skilled labor force will work closely with our customer throughout the repair and/or manufacturing process to ensure we meet their needs and expectations. We have the skills, knowledge and experience to correctly repair contemporary equipment, as well as rebuild, manufacture or update antiquated or obsolete components for improved safety and reliability. Whether its repair, modifications, or manufacturing complete, our goal is to help get you the highest quality parts as quickly as possible.

Accuracy and precision are critical when it comes to many industrial components. Cylindrical grinding is one of the best ways to achieve exact dimensional sizes, concentricity and superior surface finishes which can be crucial to the efficiency and longevity of your equipment. To support our hard chrome plating department, Precision Equipment employs and number of ID and OD grinders with OD grinding capabilities up to 32” diameter x 200” overall length.

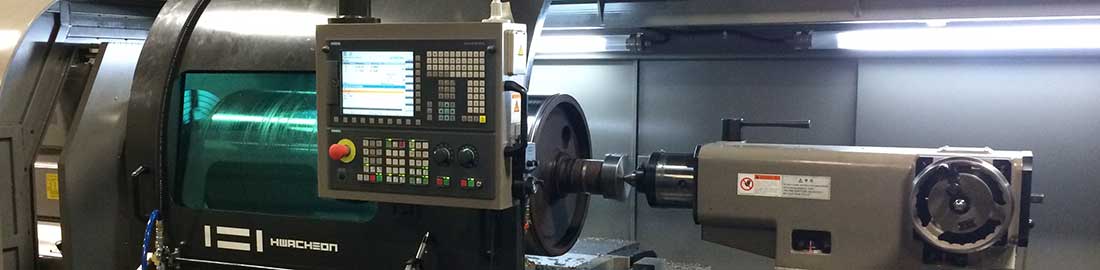

Precision Equipment’s machine shop includes CNC turning, boring and milling, conventional machining, honing and lapping. Our journeymen work force consists of skilled machinists, mechanics and designers that can accurately and properly manufacture or repair your equipment. Complete rebuilding of equipment and components is one of our specialties. We are capable of inspecting and documenting cylindrical runout down to .000050” (50 millionths of an inch) and assisting with design and component improvements upon request.

Precision Equipment has designed and manufactured cylinders for a number of industries. Our seasoned engineering staff can design cylinders to meet your requirements or reverse engineer an existing cylinder and its components while incorporating design upgrades and improvements. We are known as the telescopic truck-dump cylinder specialists in the northwest and can repair almost any style or brand of hydraulic or pneumatic cylinder.

Precision Equipment works as a subcontractor as well as directly with hydroelectric and power companies’ to manufacture, refurbish and rebuild various hydroelectric components. We specialize in Hydraulic Servo Cylinder overhauls and have the capability and knowledge to meet or exceed our customers’ requirements.

Customers include: Voith Hydro, GE Renewable Energy/Alstom, USACE, Idaho Power and Andritz.

Precision Equipment is a SUBSAFE/Level 1 qualified manufacturer specializing in hydraulic accumulator overhaul for the US Navy. Working with SUBMEPP and NAVSEA, Precision Equipment continues to be involved with the Navy’s Advanced Equipment Repair Program (AERP) and Trident Refit facilities nationwide.